Vaega Fa'aalava Maualuga Maualuga mo Fa'amama

fa'amatalaga

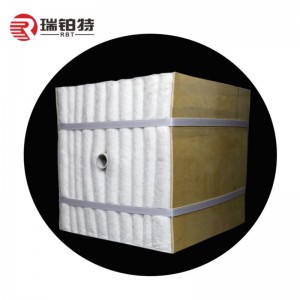

Fa'aaogāina maualuga alumini silicate fiber cotton e fai ma mea mata, fa'agasologa vacuum molding.E mafai ona faia i le tele o le density eseese o le 200-400kg / m3, ituaiga eseese o piliki, laupapa, modules, tulaga prefabricated vaega, mu, pa'u ma isi oloa faapitoa e fetaui ma manaoga o nisi vaega o alamanuia i sootaga faapitoa gaosiga, ma ona foliga ma le tele e manaʻomia le faia o mea faʻapitoa abrasive.O oloa abnormity uma e maualalo le fa'afefe i luga o la latou 'au'aunaga o le vevela ma fa'atumauina le maualuga o le fa'amama, mama mama ma a'afiaga.O mea e le'i mu e faigofie ona tipi pe fa'ameamea.I le faagasologa o le faʻaaogaina, o le oloa o loʻo i ai le lelei o le faʻaogaina ma le faʻaogaina o mea, ma e le faʻaleagaina e le tele o uʻamea uʻamea.

Vaega

Faiga o oloa: vaega tele o alava, mama mamafa, malosi maualuga, conductivity vevela maualalo, vevela teʻi tetee, machining faigofie, airflow erosion tetee, faigofie manaʻomia e pulea le density, o se compression patino, tensile, flexural malosi, foliga lavelave plasticity.

Fa'aaogāga

O loʻo faʻaaogaina oloa i alamanuia eseese o mea faʻapipiʻi vevela vevela mea faʻapipiʻi, lagolago ma le vevela vevela, mea faʻapipiʻi o le maualuga o le vevela o le ogaumu fale gaosi oloa masonry, taualuga tautau, taula ma le ogaumu faitotoa, taʻavale afi, suauʻu vailaʻau vailaʻau ma mumu, vaega pu e mataʻituina, va'a, fa'alava fa'a, tamai gutu ma tundish, fa'apipi'i lima lima mo le fa'afefeteina u'amea, fa'ainisinia fa'a'ese'ese ma so'o se su'ega fa'ailoga lavelave.

Fa'asinomaga o oloa

| INDEX \Oloa | STD | HC | HA | HZ |

| Fa'avasegaga vevela(℃) | 1260 | 1260 | 1360 | 1430 |

| Galulue Vevela(℃)≤ | 1050 | 1100 | 1200 | 1350 |

| Malosi tele(kg/m3) | 200~400 | |||

| Fa'avevela vevela(W/mk) | 0.086(400℃) 0.120(800℃) | 0.086(400℃) 0.110(800℃) | 0.092(400℃) 0.186(1000℃) | 0.092(400℃) 0.186(1000℃) |

| Suiga Linear Tumau(%) | -4/1000℃ | -3/1100 ℃ | -3/1200 ℃ | -3/1350 ℃ |

| Modulus o le malepe(MPa) | 6 | |||

| Al2O3(%) ≥ | 45 | 47 | 55 | 39 |

| Fe2O3(%) ≤ | 1.0 | 0.2 | 0.2 | 0.2 |

| SiO2(%) ≤ | 52 | 52 | 49 | 45 |

| ZrO2(%) ≥ | 11–13 | |||